Magnetic Hygiene O&G

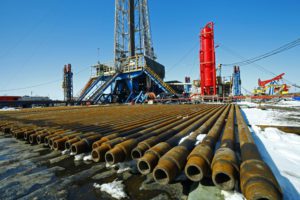

In directional drilling, the orientation of the bottom hole assembly (BHA) is determined by an assembly of magnetometer and accelerometer. In order to prevent any local disturbances, the drilling collar that surrounds the directional tool needs to be non-magnetic.

Whilst material selection during manufacture can ensure that the drilling collars are clean out of the factory, it is difficult to ensure that over their lifetime they do not develop some magnetization due to stresses.

Magnetic surveys of the drilling collars can help determine the hygiene level of the collar and isolate those which may have acquired magnetization over time.

Magnetic surveys of drilling collars

Non-magnetic collars are typically manufactured from non-magnetic steel, though these can have impurities which acquire magnetization over time. Checks of their magnetization can be done using one or two fluxgate magnetometer(s) and a suitable data acquisition system such as the Spectramag.

Whilst ideally the testing would need to be carried out in a relatively clean magnetic environment, this is rarely the case. Thus, for most scenario, the setup would use a static probe and a mobile drilling collar. This will avoid for the probe to move relative to environmental disturbances associated with anomalies in the building or surrounding equipment. For the smaller diameter a single probe within the bore of the collar will provide a good response. For the larger diameters, it may be useful to have a couple of probes in the bore against opposite walls. As the equipment which will be sensitive to the hot spots will be within the bore of the collar, this is where the fluxgate sensor should be located.

Using the Mag-13MC sensor will be more beneficial as you can then place a centralizing plastic ring over the probe in order to keep it central within the bore. Connected to the Spectramag-6 for data acquisition, the proprietary software will allow the visualization of the field in real time. The sensor could be fixed at the end of a non-magnetic pole, and the collar mounted on a non-magnetic trolley which will allow to push the collar over the probe.

Hot spots will be recognized with a change of the magnetic field on one or more axes, typically with a bipolar signature such as left.

Check of magnetic hygiene on NMR tools

Downhole NMR tools are used on oil and gas exploration to determine some of the petrophysics properties of rocks down into a borehole. These tools uses powerful magnets. Transporting them by air requires to satisfy IATA regulation that the equipment doesn’t generate a field disturbance of more than 525nT at a distance of 4.6m.

These measurements can be made with a fluxgate sensor and acquisition system such as the Mag-13 and Spectramag. The regulation calls for a total field disturbance at a given distance for the outer part of the packaging. With the Spectramag, the total field can be calculated from the 3 vectors from a Mag-13. From a practical perspective, measurements would be carried out by bringing the magnet assembly up to a distance of 4.6m and checking that the max deviation is less than the allowed maximum. In the case of long tools, a scan should be carried out along each face of the package to ensure that along the length of the tool there are no deviations more than the tolerance.

In all measurements, the probe will remain static, and the environment should remain stable during the measurements (i.e. no other equipment moving nearby as this could cause other disturbances not associated with the device of interest).