Metrology

Metrology applications require traceable measurements and measurements able to be duplicated by multiple labs. Accreditation by certified body enables labs to easily and quickly trace measurements (be they in or out of tolerance) and resolve potential deficiencies.

Electric Current

Traceable current measurements become critical in electric drive efficiency measurements for vehicle and industrial standards such as electricity metering. Measurements can be made at DC or AC for variable speed motors applications.

Danisense Zero-Flux Current Transducers make up the traceable (with measurement from NRC, Canada) calibration standard for ppm accuracy measurement at DC and AC currents. GMW offers accredited calibration for current probes from DC to 400Hz and current magnitudes from 20A to 8kA.

Bergoz Instruments NPCT DC Current Transformer acts as the one true reference measurement (displaying DC Beam Current) in nearly every Light Source Storage ring worldwide,

Magnetic Field Reference Magnetometers

Organizations such as the US FDA require MRI to have Magnetic Field “quality” (technically uniformity) to be measurable to certain levels before approval for patient use.

The gyromagnetic ratio of water (i.e. the proton) is (42.576 MHz/T and is the fundamental traceable constant (accurate to +/-5ppm) in Nuclear Magnetic Resonance measurements and the principal of operation behind Metrolab NMR Teslameters and Magnetic Field Cameras. This value is about 5ppm higher than water for the silicone rubber samples used in the teslameter.

When developing low magnetic field instrumentation, fluxgate offer a good low field reference sensor. The Bartington Mag-13MS range will be the most suitable, with the ability to provide accredited calibration by the National Physical Laboratory in the UK.

Sensors and Magnetometer Calibration

In order to calibrate magnetometers, a controlled magnetic field is required wherever the sensor is found (consumer electronics or in a compass).

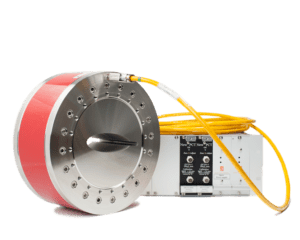

For low field (up to 10x the Earth’s field), Bartington’ Helmholtz coils are available. With orthogonality compensation they are ideal for the calibration of precision magnetometers as well as compasses, AHRS sensors (Attitude and Heading Reference System), downhole tools for the oil & gas industry or even the magnetic sensors used in consumer electronics.

The coil is used to generate a known magnetic field in any direction, thanks to the three-axis, with an independent control of current through each of the coils using GMW’s Helmholtz coil control software. It offers users the ability to perform calibration in their manufacturing facility directly without having to resort to find and travel to an area of low natural gradient, and stable field over time which would be required to perform total field calibration methods (relying on the Earth’s field). The use of a Helmholtz coil will greatly facilitate and speed up the manufacturing and calibration process.

The active compensation system available enable the use of the system in a less ideal environment, quite typical for manufacturing settings.

For the calibration of higher field sensors, the range of electromagnets available can enable you to perform high accuracy calibration with fields in excess of 3T. These are ideal for the calibration of hall sensors.