Current Clamps:

What they are, the different types, and their applications

Current clamps are devices with jaws that open up and clamp around an electrical conductor to measure current. They are very useful as they allow you to clip the probe around an existing conductor without having to disconnect and reroute cables.

Current clamps will read the magnitude of direct current (DC) and alternating current (AC) as well as the phase shift and waveform. In this article, you’ll learn the ins and outs of current clamp technology, the applications, and the best types of current clamps to use in challenging environments.

Table of Contents

- What Current Clamps Do

- Current Clamp Accuracy

- What are Current Clamps Used For?

- How to Use a Current Clamp

- How do you Read a Current Clamp?

- The Different Types of Current Clamps

- Measuring DC with a Clamp-on Current Probe

- The Working Principle of a Coreless Clamp-on Current Probe

- The Hall Effect and why it’s used in Current Probes

- What is True RMS?

- GMW Associates Current Clamps

What Does a Current Clamp Do?

A current clamp measures electric current flowing through a wire, cable,busbar, or other conductor. The analog output of the clamp can be read by a voltmeter, oscilloscope, power analyzer or DAQ. It allows you to measure the current in a conductor without having to alter or disconnect the cable.

Clamp-on DC/AC Current Measurement

How Accurate are Current Clamps?

Current clamps vary widely in accuracy.

A high-end current clamp can get better than one percent accuracy, while less expensive current clamps range from five to ten percent accuracy.

What Are Current Clamps Used For?

Current clamps are great for measuring currents in hard-to-access areas. They’re often used for monitoring and quality control to ensure current is flowing and flowing at the correct magnitude. You can use them for motor testing to know what the primary current is, as well as phase and waveform information to check power efficiency. Current clamps are used in all kinds of applications where you think or know current is flowing, but cannot easily disconnect or get to the conductor.

How Do You Use a Current Clamp?

Current clamps have a hinge that allows you to open the clamp and then close it back around whatever you wish to measure current on. Most of the time you’ll be measuring current flowing through a wire, busbar, or lead of some kind.

How Do You Read a Current Clamp?

The most common thing people use to read a current clamp is an oscilloscope. However, if you’re looking for just a DC reading or the RMS reading, you can use a digital voltmeter. Other instruments that can read the output include an ADC (analog to digital converter), a data logger, or power analyzer.

Clip-on AC/DC Current Measurement

What are the Different Types of Current Clamps?

There are several main types of current clamps.

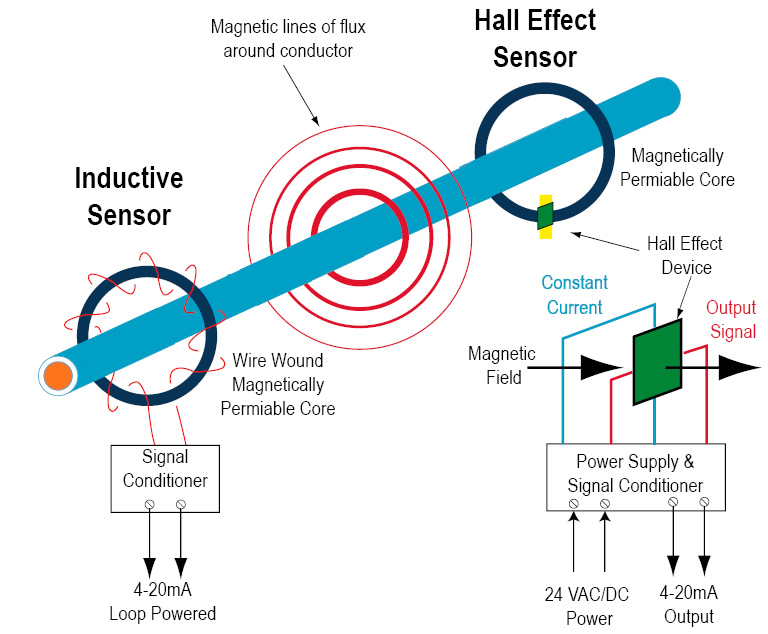

Current Transformer Clamp Current Probes

These passive transformers are typically used by electricians to bypass the older method of cutting into a wire and inserting meter test leads into a circuit to take in-line current measurements. The jaws of the clamp meter do not need to touch a conductor in order to get an reading. Transformers can only measure AC current, and are generally the least accurate.

Flexible Current Probes

These clamps measure only AC current. Flexible and lightweight measuring heads utilize the Rogowski Principle and allow for easy installation in hard-to-reach areas. The Rogowski current clamp is a coil without any magnetic core. The magnetic field produced by the conductor induces a voltage proportional to the rate of change of the current. The voltage is then integrated in an analog circuit to produce a voltage proportional to the current magnitude, suitable for multimeters, oscilloscopes, and recorders.

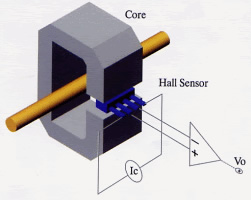

Open Loop Current Clamp Probe

Most open loop current probes measure both DC and AC current up to 1000’s of Hertz.

Similar to a current transformer, open loop current clamps have a magnetic core, but rather than being continuous, there is a small gap or “slit” cut into the core. The magnetic field generated by the conductor is concentrated across a gap in the core. When the magnetic field (flux) comes to that small air gap in the core, a small magnetic field sensor (often a Hall effect sensor) sitting in the gap produces a voltage proportional to the magnetic flux in the gap and translates it into a current reading. Because there is a gap in the magnetic core of the sensor, this is sometimes referred to as a Gapped Core Current Sensor.

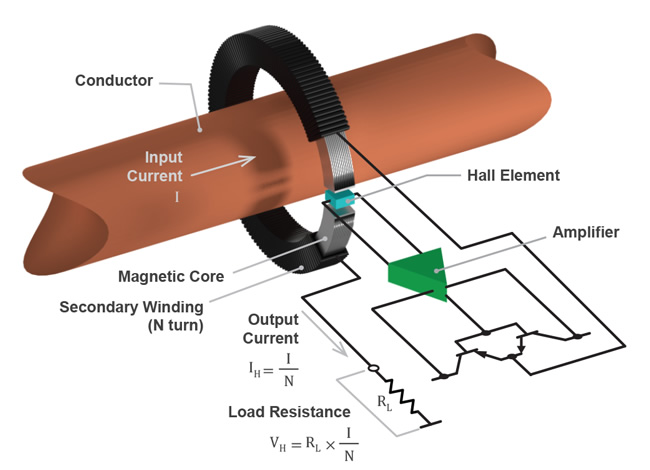

Closed Loop Current Clamp Probe

While less common with a current clamp, another type of current sensor is called Closed Loop. These are more common with current sensors that have a fixed aperture and do not open.

A closed loop current sensor has a secondary, feedback winding wrapped around the magnetic core. This feedback winding uses a measurement of the magnetic flux within the core, sometimes with a Hall effect sensor, and often other types of sensors, to cancel out the magnetic flux from the primary conductor so the magnetic flux in the core is zero. Closed loop current sensors are often higher stability, higher linearity, and higher accuracy compared to open loop current sensors.

Coreless Current Clamp Probes

Coreless current sensors, similar to the flexible Rogowski Coil mentioned above, uses no core at all. Instead, an array of sensors in the current clamp samples the magnetic field generated by the current passing through the conductor at various points, calculates the total field, and outputs a signal proportional to the current. Because it is coreless, coreless current clamps share many of the benefits of a flexible Rogowski Coil including include much lighter weight, thinner cross section, instant recovery from overload, no magnetic hysteresis, and tolerance for harsh environments.

CLIP AROUND AC Current Probes

Can I Measure DC Current With a Clamp-on Current Probe?

It will depend on the technology one uses. If you’re using a Rogowski Coil or passive transformer clamp-on current probe you will not be able to measure DC current. However, if you’re using Hall Effect technology or another magnetic sensor that has a DC response, these clamps will measure DC current. If you need to measure DC, always double-check the specification of your current clamp first.

What is the Working Principle of a Coreless Clamp-on Current Probe?

Coreless current probes use many magnetic sensors (often, but not always, Hall effect devices) spready around the circumference of the coreless current probe. Each magnetic field sensor measures the field generated by the current-carrying conductor. The total magnetic field is calculated from the individual sensors, and from there converted into a voltage output signal. A coreless current probe is neither open loop or closed loop – it is

something different.

The disadvantage to not having a magnetic core is sensitivity in measuring very small currents. The advantages of not having the magnetic core are less weight, more affordable cost, and you cannot saturate it. You will not have issues driving too much current through the probe and damaging it like you will with a magnetic core clamp-on current probe.

What is the Hall Effect and why is it used in Current Probes?

The Hall effect was discovered by Edwin Hall in 1879. He was exploring the details of the interaction between magnets and electric current. Hall wanted to know if magnetic fields interacted with the conductors or the electric current itself.

Today, Hall effect devices are used by the many millions in industrial processes. Most applications of Hall effect devices are focused on measuring a magnetic field. In effect, it’s a non-contact magnetic field measurement.

One of the big advantages of measuring current with Hall effect technology is that it can be part of an integrated circuit. As a result, it’s very small and very inexpensive to manufacture.

Which Type of Current Clamp Uses Magnetic Field Around a Current-Carrying Conductor to Measure Current?

A coreless DC device as described above. The main thing to keep in mind with these types of current clamps is the design and engineering advantages for their intended application. They’re optimized for higher currents. With a coreless device, you can measure 16,000 amps with the same footprint you’d use measuring 200 amps. Measuring the current strength with a magnetic core clamp would require a very heavy device that might weigh 20 pounds versus just a few ounces.

What is a True RMS Clamp-on a Current Probe?

A true RMS implies that it’s an AC current being measured. What you’re looking for is the value of the RMS current. Take a power frequency of 60 Hz for example, which is typical in homes. You know that the frequency is fixed. What you want to know is just the value of that. What you end up getting is a DC output for an AC input. The RMS is more of an average measurement. This is useful if your goal is just to know what the current is in the line and don’t care about the actual frequency content.

Which Instrument is Used to Measure Both AC and DC?

DC-AC coreless current probes works for both DC and AC. The frequency measured is typically in the tens of kilohertz. The question is what are you specifically looking for? As we just discussed the RMS current gives you more of an average, or are you looking for the current at any instantaneous point?

AC & DC Current

Transducer Calibration

How Many Wires Can You Clamp with a Current Clamp at Once?

The short answer is “as many as will fit!”

The real question is to ask why you want to clamp the probe around multiple wires. Remember that the clamp is going to measure everything through the aperture. So if you put two wires through the clamp, it’s going to measure the sum of both. It will not differentiate between multiple wires. If you put in two wires that are current flowing in opposite directions, it’s going to take the difference.

For example, if you have two wires that are meant to be reading the same current, but one is failing, you might see the difference between the two.

Somewhat related to this is having one wire wrapped around the clamp and you put two turns through the clamp, it will measure both turns, doubling the sensitivity

Let’s say you have a bundle of cables and you only want to measure one. You can slip the jaws of the clamp around that one cable, with all the other cables remaining outside the jaws, and get that single cable measurement. Everything outside is rejected. So you can differentiate between multiple wires in a bundle by being able to get a small enough clamp in that space between the individual wires or around a busbar in a tight spot.

Considerations When Buying a Current Clamp

The first thing you need to identify is the type of current(s) you’re measuring. Are you measuring DC current, AC current, or both? How large is the primary conductor you need to workaround? Is it a cable bundle or very thin wire? If you’re measuring AC, you’ll need to determine the frequency (or pulse length if not repeating signal) you need to reach. In a home, your AC frequency will be 50 or 60 Hertz. If you’re testing motors you’ll need many harmonics and kilohertz of frequency. You’ll also take into consideration the accuracy and resolution. Finally, weight, size, and operating conditions should be accounted for – think temperature, vibration, water, and dust.

Measuring Ranges and Designs of Current Clamps

Many current clamps are in the one-inch aperture range. These common clamps can measure from 10 to a few hundred amps. There are also larger less common current clamps that have up to a six-inch aperture while maintaining lightweight. These current clamps are capable of measuring from 250 amps up to 20 kiloamps.

GMW Associates Current Clamps

GMW Associates offers a wide selection of current clamps and sensors for both industrial and lab applications. The clamps are extremely lightweight, vibration, dust, and splash resistant, and cost substantially less than alternative measuring devices like oscilloscope probes.

For example, the GMW Associates current clamps can be used to test electric vehicles in varying environments. The dust, vibration, splash-proof components, and temperature range allow consistent and accurate measurements whether you’re testing in cold frost or hot desert environments.

The GMW Associates current clamps were born out of customers asking for something like a Rogowski coil that measures DC, not only AC. We listened, and our clamp-on probes can measure both DC and AC.

Request Help/Info

If you need to contact someone specific, please visit our Contact Info page. Thank you!

Request Form